We are having trouble at this moment

Update your browser while we check what is happening

Back homeUpdate your browser while we check what is happening

Back homeOne of our experts will contact you as soon as posible

Back home

RHOSONICS is proud to present a new generation non-nuclear density meters based on ultrasonic technology. After years of being successful as the only alternative for nuclear technology in density measurement of abrasive slurries we introduce the Rhosonics SDM Slurry Density Meter. This new density meter makes use of the same ultrasonic technology but with new materials, better electronics and innovated calculations. These improvements result in higher accuracy and better stability of the new density measurement device

The Rhosonics Slurry Density Meter has its sensor, analyzer, cable and software integrated in just one system. Therefore, the new density meter weighs less than its predecessor. In addition, the ‘HART’ protocol is integrated to improve communication. The SDM has new sensor material and is therefore suitable for new and more challenging applications.

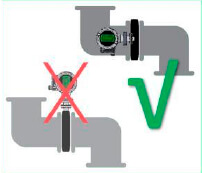

The Rhosonics Slurry Density Meter with wafer installation

SDM is used in the following industries:

The Rhosonics SDM has a single probe, employing a unique measuring technology. This enables very accurate density measurements in light to very dense slurries.

The SDM uses new sensor technologies, the PEEK material is replaced by a ceramic material. This gives the probe better ultrasonic properties like a stronger and more intense signal.

The sensor tip is extended which results in a longer life cycle of the new sensor. The sensor and housing can be easily separated which makes the SDM very flexible in case of maintenance.

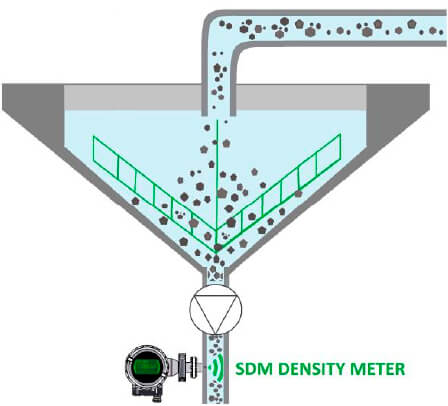

Density measurement in the slurry of a thickener underflow

SDM density meter can be used in many applications to measure the density of a slurry. For the mining industry, typical applications are a thickener underflow and a cyclone feedline. Also applications like dredging, power plant ash, lime stone milk and many others are possible. The measured density value is used for process control but also in combination with flow measurement for production yield. The Rhosonics ultrasonic density meter is in general THE alternative for nuclear density technology for heavy slurries with a high abrasive impact.

Rhosonics offers different installation methods to fit every customer’s need. The major installation methods are discussed below.

An UFTC is a metal pipe piece which can be mounted between two flanges. The spool type and size are on customers request.

Rhosonics designed a special low cost Weldolet solution for very abrasive applications, such as dredging. The Weldolet can be installed by drilling a hole of 36 mm in a steel pipe. On the outside of the pipe, the Weldolet is welded-on so the sensor can be fitted in.

The UWC (Ultrasonic Wafer Cell) is a synthetic 60 mm thick ring made of UHPE (Ultra High Density Poly Ethylene). It can be clamped between two flanges in almost every pipe system. Rhosonics always tries to guarantee the maximum performance and therefore produces custom-made wafers. The thickness of a liner (if present) and the internal diameter of the pipe are important dimensions to guarantee flush mounted installation.

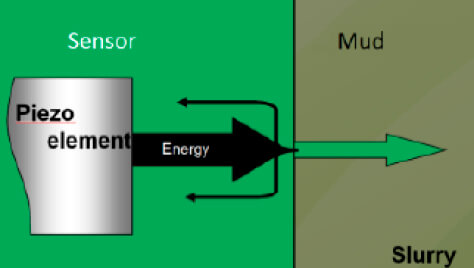

The density measurement is based on measuring the acoustic impedance of the slurry.

Z = C x p

Z = Acoustic Impedance

C = Sound Speed

p = Density

The attenuation of the ultrasonic signal is measured, which is translated into density.

Ultrasonic measurement principle

Do not wait any longer, allow your company to grow efficiently with information useful for your business.